Wafer Scale - Trilogy Systems: Part 1

Cerebras isn't the first to try to use 'wafer-scale' to break into a lucrative market.

When he founded Trilogy, it was as if he proposed to create the world in five days rather than the previous record of six. But why not, given his reputation for near omnipotence?

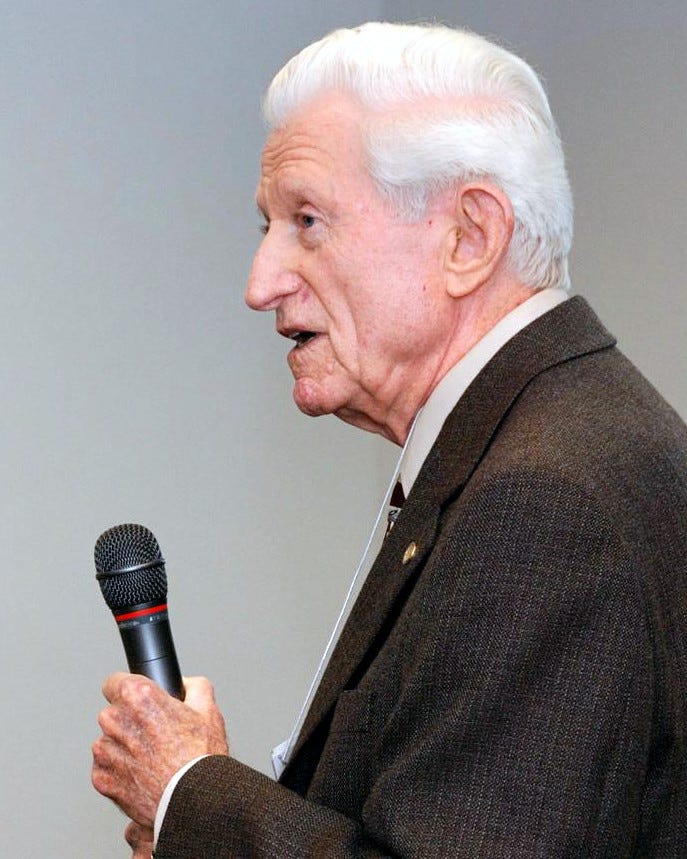

CNN on Gene Amdahl

One of the recurring themes of this Substack is that some of the ideas underpinning the latest innovations have been around for a long time. They may not be widely used, but they stay around until the right supporting technologies or commercial applications emerge to make them viable.

Take modern AI. Artificial neural networks date back to the 1940s. Systolic arrays, used in Google’s TPUs, have been around since the 1970s. And now, completing the trilogy, we see Wafer-Scale Integration (WSI) - creating huge integrated circuits from an entire silicon wafer - making headlines.

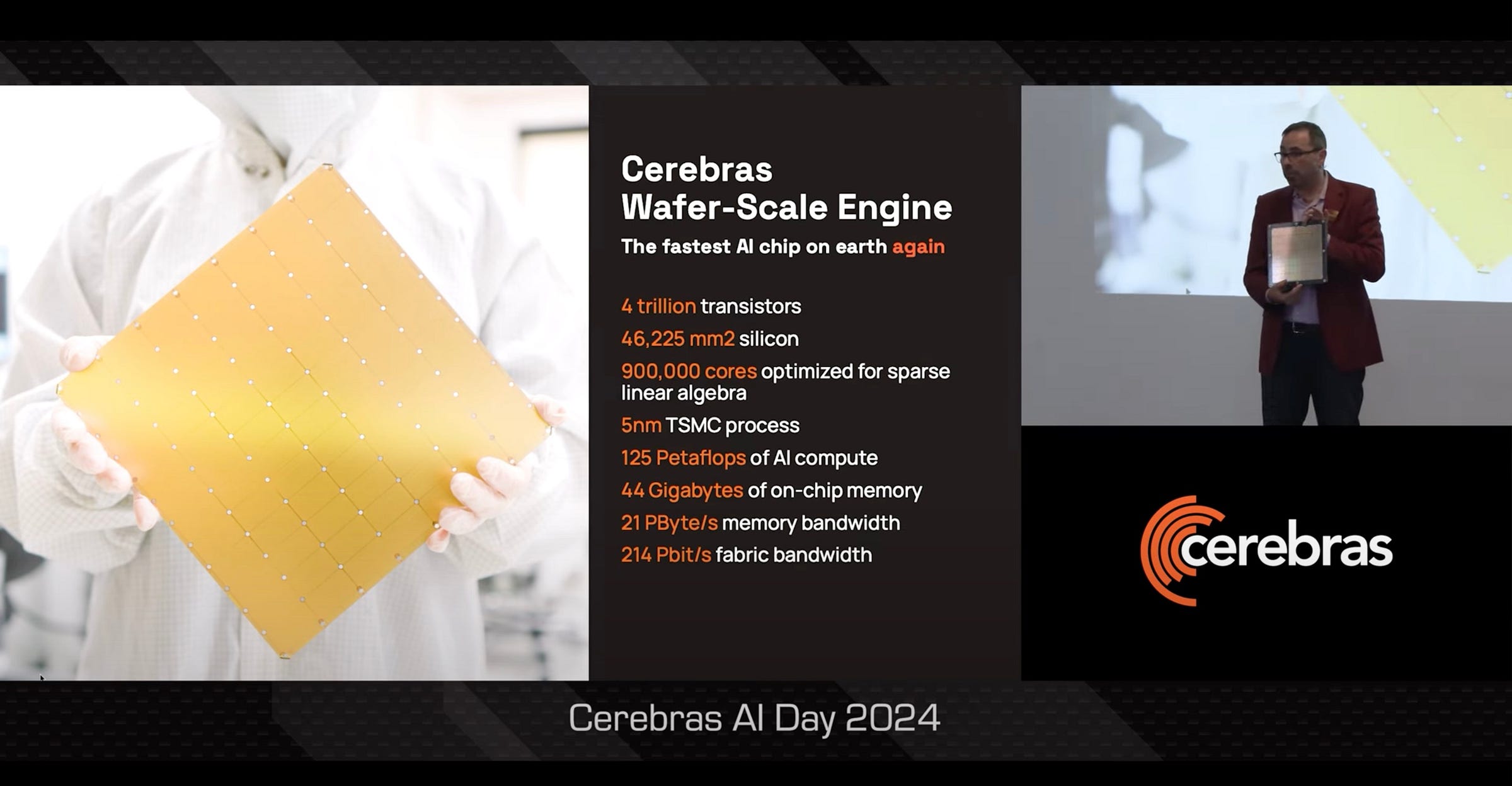

WSI is in the news because Cerebras has filed for an Initial Public Offering on NASDAQ. Cerebras makes systems designed to accelerate AI training and inference, competing with established firms like Nvidia and AMD. Using dinner-plate-sized wafers is one key way they distinguish themselves from competitors.

Cerebras talk about their work on WSI with perhaps just a touch of hyperbole.

Wafer-scale integration was once thought to be impossible, but Cerebras has turned the impossible into reality.

And for some Cerebras is more than a little controversial.

Cerebras was founded in 2015, but the idea of WSI goes back much further. Almost from the first day integrated circuits were cut from silicon wafers, researchers have been intrigued by the idea that the wafer might be left intact.

WSI already had a ‘history’ as far back as 1984, when as distinguished a figure as Jack Kilby, the co-inventor of the integrated circuit felt it was important enough to write the paper: ‘Wafer Scale Integration - A Historical Perspective’.

What attracted Kilby and others to WSI in the 1980s? In an era when the most powerful systems used many integrated circuits with just a few thousand transistors, creating a ‘super-chip’ from a single wafer offered the possibility of more powerful designs with less expensive, fiddly, and unreliable wiring.

A moment’s thought though, and lots of problems appear. How would engineers deal with multiple defects on the wafer? How would they dissipate the heat from all those circuits? Would the economics of these ‘super-chips’ work?

Any firm that could overcome these obstacles might gain a decisive competitive advantage. At the time of Kilby’s paper, one firm, Trilogy Systems, led the effort to make WSI a commercial success.

Trilogy was co-founded by Gene Amdahl, the chief architect of the IBM S/360 mainframe computer, and founder of Amdahl Corporation, the successful IBM mainframe clone maker.

Like Cerebras, Trilogy Systems faced powerful competitors, including IBM, Gene Amdahl’s old employer, and Amdhal Corporation, the company he founded. And like Cerebras, Trilogy faced intense scrutiny and its finances were highly controversial.

Gene Amdahl’s skills and reputation were key to Trilogy’s ambition and the financial support the firm attracted, so we need to start with Amdahl and his pre-Trilogy career.

Gene Amdahl, IBM and Amdahl Corporation

The objective of this thesis is to describe the logical design of a general purpose digital computer presenting the arguments underlying the final choices of operation and components.

So started Gene Amdahl’s PhD 1953 PhD Thesis.

Today Amdahl is often remembered as the author of ‘Amdahl’s Law’, a formula that defines limits to computer performance improvement. However, Amdahl’s influence on computer architecture and some of the most powerful and important computers of the 1950s, 1960s, and 1970s was immense.

While working on his PhD Amdahl created the designs for his first computer, the Wisconsin Integrally Synchronized Computer (WISC).

He joined IBM in 1952 and, for more than a decade, worked on designing many of IBM’s most powerful early computers. There was the IBM 704, the first mass-produced computer with floating-point hardware. IBM’s ambitious STRETCH mainframe followed. He then acted as chief architect of IBM’s hugely successful and enduring mainframe design, the System/360, which first shipped in 1964.

Today’s IBM mainframe systems are the direct descendant of Amdahl’s IBM System/360. Your airline booking or tax calculation is likely to take place on a system whose architecture is compatible with Amdahl’s designs.

Amdahl left IBM in 1970 and set up Amdahl Corporation, the first company to build IBM-compatible (or so-called ‘plug-compatible’) mainframes. Amdahl Corporation’s first machine, the Amdahl 470V/6, which shipped in 1975 was cheaper and faster than a comparable IBM machine, yet ran IBM S/360 and S/370 mainframe applications.

It’s worth emphasizing how bold this was. Building a 100% IBM-compatible mainframe was an enormous technical challenge and going head-to-head with a company as powerful as IBM was a hugely risky strategy.

Yet Amdahl Corporation was soon successful, with its high-end IBM-compatible mainframes that sold for lower prices. In 1978 Amdahl Corporation had sales of over $330m and profits of $45m.

IBM finally responded with major price cuts in 1979 and Amdahl Corporation plunged into losses. Gene Amdahl disagreed with his colleagues about the company’s direction and resigned.

Trilogy Systems

Within months Amdahl started a new venture, Trilogy Systems Corporation, setting up an office in Santa Clara in August 1979. The following year he was joined by his son, Carlton (Carl), a technology entrepreneur in his own right.

Amdahl’s expertise was in mainframes so Trilogy would again take on his former employers IBM and Amdahl Corporation in the IBM ‘plug compatible’ mainframe market.

How would Amdahl compete with these established players? Computerworld magazine in June 1981 offered some clues:

Trilogy plans to introduce a system that it claims will represent a significant breakthrough and a different approach to the technology of very large-scale integration (VLSI). "Although the product will be based on VLSI technology, it offers a different approach at the design level than that so far tried," ... "It is semiconductor-based and aims to simplify things by eliminating some components or parts."

To support this ‘breakthrough’, Trilogy indicated that it would need to build (multiple) fabs to manufacture VLSI integrated circuits for its new computers:

… Trilogy has been negotiating with the Irish Development Authority with a view toward setting up a manufacturing plant in Ireland, where lucrative tax advantages are to be gained. If the plan goes through, Trilogy would make its own semiconductor devices in the U.S. and ship them to Ireland, where the rest of the production facilities would be based.

Trilogy is also looking at building a chip plant in Ireland …

Trilogy would need a head office too so in August 1981 work started on building a 240,000 sq ft facility in Cupertino.

All this - R&D, fabs, and production facilities - would not be cheap, and a cost of $100m-$120m ($350 to $420m in 2024 dollars) was soon quoted. Gene Amdahl had sold most of his shareholding in Amdahl Corporation but Trilogy would still need substantial external investment.

Amdahl was unhappy that he had given up control of Amdahl Corporation so, not content with innovating in its technology, Amdahl and Trilogy, soon innovated in financing.

Following his experience at Amdahl Corp., where much of the company's ownership went to outside investors, Gene Amdahl, founder of Trilogy was keen to avoid the pitfalls inherent in traditional venture capital financing. Indeed, some industry sources claim Amdahl's departure from the company that bears his name was motivated by the fact that, after doing so much of the work himself, the rewards were being grabbed by others.

Under the limited partnership scheme, Trilogy set up a separate entity - Trilogy Computer Development Partners Ltd to finance the development of a large IBM-compatible mainframe. The company offers individual investors a stake in the partnership in return for finance.

Trilogy Computer Development Partners would fund the research and development that Trilogy Systems needed:

Under the arrangement, the partners invest in the R&D partnership to finance development work of a large computer system. Once the technology has been developed, Trilogy has an option to acquire the license to the technology, and in re-turn, the company will pay royalties to the partnership for products that incorporate that design.

Investors were warned that the development of Trilogy’s technology was a major risk:

It said that among the major risks that prospective investors must be prepared to accept are "substantial and difficult technical problems in developing the advanced, very large-scale integrated [VLSI] semiconductor circuitry necessary for the success of the computer design."

Trilogy raised $55m using this new approach and a further $30m from venture capital investors.

In October 1981 the company held its first press conference and shared more about Trilogy’s products, ambitions, and technology. Announcing plans for the 1984 launch of IBM-compatible mainframe systems, Gene Amdahl was quoted as saying:

… we believe we have something in our technology that will give us a unique capability. With this technology, we plan to be about 50% faster than the fastest computer in 1984,"

Precisely what this technology would be though remained mysterious. When Amdahl broke ground in Trilogy’s new plant in Blanchardstown, County Dublin was still not prepared to give up Trilogy’s secret:

Gene Amdahl stirred but did not remove the veil of secrecy surrounding Trilogy's very highly integrated computer technology. Emphasizing that the four-year production plan for the machine is "on target," Amdahl said only that the computer would feature emitter-coupled logic circuitry and would have "a factor of three improvement in performance" over any computers existing in 1984.

By now Trilogy was saying that the price tag for the future investment required to support this innovation had risen to $160m.

Wafer Scale Revealed

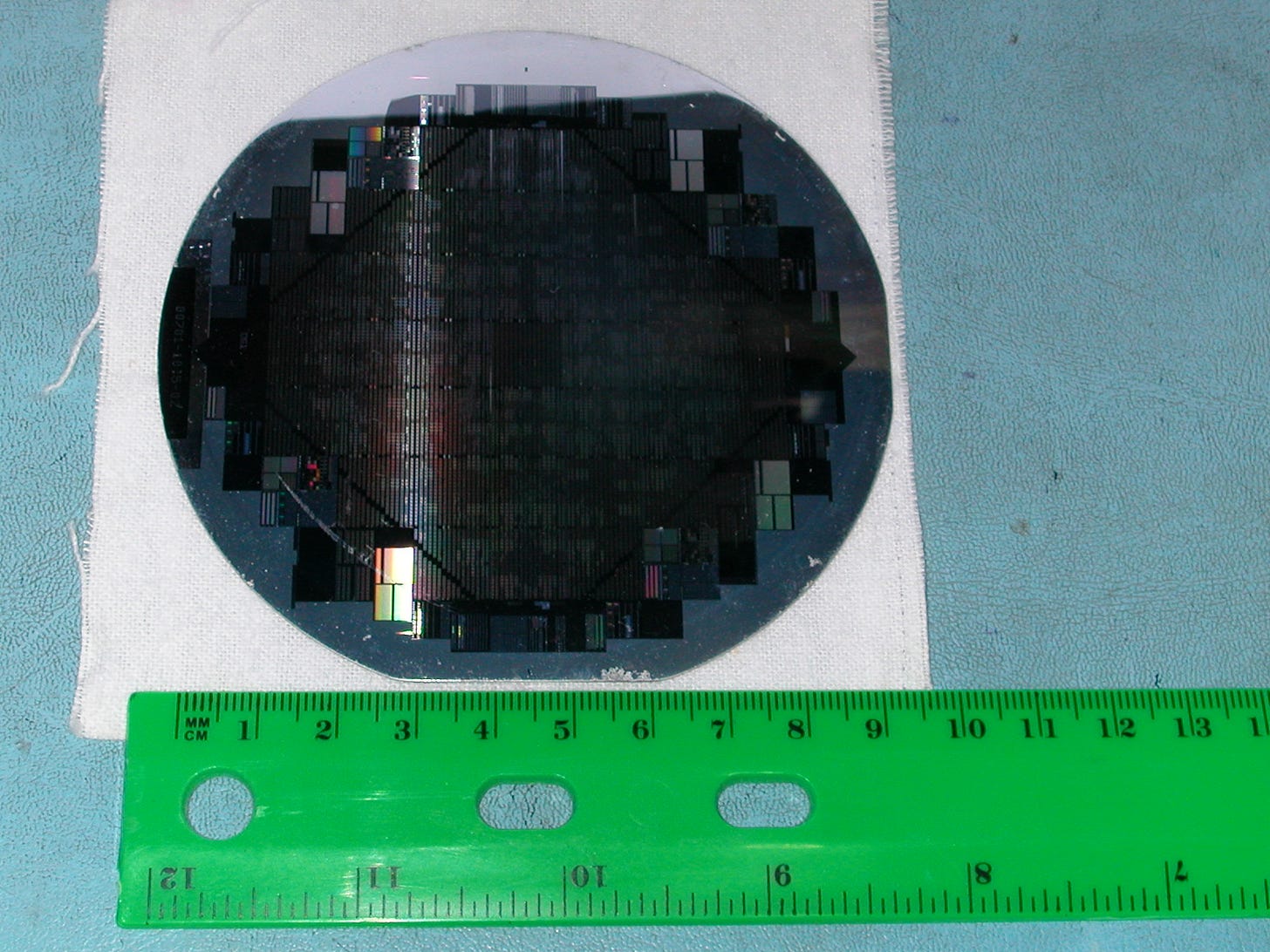

Finally, in 1983, Amdahl revealed the technology ‘breakthrough’ that would underpin Trilogy’s new systems: Wafer Scale Integration. In an article in Datamation magazine Gene Amdahl and colleagues shared more details of Trilogy’s innovations and the benefits they would bring.

… a funny thing has been happening to Trilogy on its way to the market-place. Like a race car builder choosing rocket propulsion over the internal-combustion engine, Trilogy has decided to leapfrog the integrated circuit and go to wafer-scale integration. It is developing a logic chip that measures 6 centimeters on a side, approximately 2½ inches square, using high-speed ECL technology.

Each of Trilogy’s wafers would replace around 120 integrated circuits in an IBM mainframe.

It could be compared with IBM's thermal conduction module (TCM), which holds 120 IC chips. In terms of its functional characteristics, Trilogy's wafer/chip contains about two thirds the logic of a TCM, but it has about twice the power of a TCM because it runs so much faster.

What would Trilogy’s WSI technology deliver?

We will probably have three models, one that's twice as fast as IBM'S fastest today, one that's three times, and one that's four times faster."

In addition to the ability to run faster, WSI had a key advantage over IBM’s approach: it removed the need for hundreds of fault-prone interconnects between smaller integrated circuits. Instead, Trilogy had to deal with defects in its wafers. Carl Amdahl explained the approach they were taking.

"What we've developed is a process whereby through redundancy, having multiple copies of the circuits on a big chip, we can tolerate defects," … "So we would expect on this chip between 300 and 400 defects. And with the redundancy strategy, we have overcome the limitations of traditional technology."

Patents, filed by Trilogy Systems shed more light on how this redundancy would be achieved. For example, US Patent 4,621,201 assigned to Gene and Carl Amdahl and Robert Reinschmidt outlines the ‘voting’ process used to identify faults:

A circuit structure, and method for forming the structure, permits wafer scale integration by fabricating plural copies of the circuit in integrated circuit form, and interconnecting predetermined circuit element groups of the copies in a manner that permits a majority voting operation to take place. In this manner, defective circuit elements are masked by being out-voted by corresponding non-defective circuit elements that participate in the voting process.

and gives more details of how the voting system is to be implemented:

Each circuit element group is defined by a single functional output of that group, and for each circuit element group found in one circuit copy there is a corresponding and and electrically and functionally identical circuit element group to be found in each of the other circuit copies formed on the same die. The output of each circuit element group is operably coupled to that of the corresponding circuit element groups in a manner that permits a "voting' to take place, producing therefrom a voted output signal that is representative of a majority of the received signals produced by the inter coupled circuit element groups.

If Trilogy had overcome many of the obstacles to the successful implementation of WSI then it would have wide potential application. Amdahl envisaged that WSI could be implemented in other technologies.

… that Trilogy's self-repairing designs can also be implemented in CMOS or gallium arsenide, meaning it has wide applicability. Trilogy's chip, which he· describes as "like a macrocell-type of array, " is like a gate array. It consists of a number of transistors that can be put together in different groupings. It will have from 20,000 to 40,000 gates, considerably more than the largest bipolar gate array now available, one with 2,500 gates.

So Trilogy also started to look beyond the IBM-compatible mainframe market and at licensing its technology to other computer manufacturers. Cii-Honeywell Bull was first with a 3% stake.

the French Cii-Honeywell Bull has the right to manufacture the chip in France for its own use and is expected to use this technology in its next machine. But Trilogy, in addition to selling licenses on a royalty basis, could also someday become a "systems foundry"- producing chip designs and even custom chips for others.

After Cii-Honeywell Bull came Sperry Corporation which invested $42m in June 1983.

For its $42 million, Sperry acquires the option to use this technology for its own systems, for everything except IBM-com-patible products. It also gets preferred stock that represents a 15% equity position in Trilogy Ltd., the parent organization.

Soon after, minicomputer maker DEC followed suit with a $26m investment in Trilogy, again linked to access to Trilogy’s WSI technology

Digital Equipment Corp last week purchased a 9% stake in Trilogy Ltd. that gives the minicomputer giant the option to license Trilogy's untested but promising wafer technology.

DEC's $26 million investment marks the first time the company has bought an equity interest in another company. The agreement not only gives DEC the option of incorporating Trilogy's circuit technology into what most industry analysts predict will be the next generation of VAX-11 superminicomputers, but also the option of having Trilogy build a semiconductor manufacturing facility that would produce the chip for DEC's products.

Throughout all this period Trilogy continued to get major coverage in the computer trade press. In May 1983 Datamation magazine asked firms with IBM and compatible installations about their interest in Trilogy. Almost a third of the Amdahl Corporation sites indicated an interest in the - as yet unannounced and unavailable - systems from the new firm.

But this was the peak of positive news and coverage of Trilogy. Over the next year, it would become clear that the company and its technology were in trouble. We’ll tell the story of what would happen to Trilogy in Part 2.