Inmos and the Transputer - Part 1 : Parallel Ventures

A transatlantic startup takes on Intel and tries to change the world

Today’s post is about an ambitious transatlantic startup that set about competing with industry giants, including Intel, whilst simultaneously single-handedly moving computing to a parallel, multi-processor future.

Was it decades ahead of its time or was it doomed to failure, and what can we learn from the story?

When Robin Saxby became CEO of ARM, he set out to make the company follow a strategy that was very different from microprocessor market leader Intel. ARM wouldn’t make chips and would avoid competing directly with the US firm.

Saxby’s emphatic decision contrasted with the approach of another British microprocessor designer that had followed a strategy that, in some ways, was almost a copy of Intel’s. A startup in the late 1970s, it both designed microprocessors and built them in its own fabs. It also manufactured memory chips that competed with Intel’s. Even the company’s name looked like an imitation of the US giant’s: Inmos.

The story of Inmos is fascinating because many of the underlying themes are still relevant today. What role should government support play in the development of advanced semiconductor design and manufacturing? What are the pros and cons of vertical integration?

The story also centres around the idea of going from a few cores to parallel many-core systems. About how to deal with challenges such as how the processors in these systems should communicate with each other and what software should these systems run?

Today, of course, we have firms making staggering levels of investment in tens of thousand of GPUs all running in parallel to train enormous machine learning models.

I worked at a firm that used Inmos products in the 1990s, chosen because they were seen as the most cost-effective way of getting strong floating-point performance on the desktop. In that sense, these products were a precursor of today’s GPUs.

Some aspects of the story of Inmos will contrast strongly with today’s world. Most strikingly, how little it cost to set up a brand new semiconductor manufacturer.

With an initial investment of less than $100m, not only did the founders of Inmos set out to build a world-class designer and manufacturer of memories and microprocessors. They also set out to radically change the design of computer systems. They would try to do that with a new microprocessor, called the Transputer, specifically designed as the building block for computer systems with many processors.

In this post, we’re going to cover the early history of Inmos and the Transputer. In this week’s supplementary post for paid subscribers, we’ll look in more detail at the Transputer. There are quite a few surprises. I think it's fair to say that the Transputer was a highly innovative design, with features that made it uniquely suited to its role as the building block for parallel systems.

If you value The Chip Letter,then please consider becoming a paid subscriber. You’ll get additional weekly content, learn more and help keep this newsletter going!

Let’s start with the origins of Inmos, which can be traced back to a bar in Toronto in the Summer of 1977.

The Invitation

“How would you like to set up a semiconductor company?”

Those words came from Richard Petritz, who’d been the director of the TI lab where Jack Kilby had earlier invented the integrated circuit. He’d gone on to found Mostek, then the leader in the market for Dynamic Random Access Memories. So it was an invitation that needed to be taken seriously.

It was directed to Iann Barron. Barron had just finished a gruelling 36 hours, with little or no sleep, travelling to a computer conference where he and Petritz had been speaking. The conference itself had been chaotic, with renowned computer scientist Edgar Dijkstra insisting on playing the piano to his audience rather than talking about his speech. So Barron was tired and in no fit state to respond.

“And I ignored him. I was so out of it. And he asked me about three times. And I, I just never said anything to him. And then the next day I thought, oh, you know, what was all that about? But he had gone. He wasn’t there any more.”

By chance, Barron ran into Petritz again a few days later at Toronto airport, and then on the flight out of Canada, the two men started to talk more seriously about Petritz’s proposal.

Petritiz was convinced that the time was right to start a new semiconductor company:

“By 1977 it was as clear as the nose on your face that the very large-scale integration circuit was going to have a revolutionary effect on the semiconductor industry. Also, at the same time, the industry was drifting from Bipolar to MOS technology and I could see this would give rise to a whole new set of companies. It was going to be just like the late 1960s again.”

Barron also liked the idea of starting a new company. He had a vision for an innovative microprocessor. Petritz brought the semiconductor experience and a team, most notably, Paul Shroeder, who had been the chief memory designer at Mostek.

There was one issue, though. Barron didn’t want to leave his native Britain and move to the US. So Petritz made an offer. If you can raise the funds for the business, then the microprocessor part of the company can be based in the U.K.

Barron’s experience put him in an ideal position to work with Petritz on the UK arm of a new company. He’d shown interest in computers in his teens, in the early 1950s, and had gone on to study at Cambridge University, encountering the early pioneers of computing in the UK.

Combining his interest in computers with entrepreneurial drive, he’d founded his own company, Computer Technology Limited (CTL), maker of an innovative minicomputer called the Modular One. The Modular One, a machine that had a lot in common with DEC’s PDP minicomputer range, had a degree of success in the UK, but soon found itself struggling against its bigger US rivals.

After leaving CTL, he had embarked on a career in consulting. Britain’s Labour government had established the National Enterprise Board (NEB), a sort of state-sponsored firm, to invest in what were thought to be nationally important industries. Barron knew the NEB and that they were interested in computers. As a consultant, he had prepared reports for them on minicomputers (not worth bothering with as they would be soon superseded, was his conclusion) and the U.K. semiconductor industry (impossible to rationalise).

So Barron thought that maybe the NEB might invest. All he needed was a business plan. Handily, Petritz already had one. He’d previously discussed setting up a new semiconductor company with the South Korean government, and so quickly repurposed his Korean plan. Petritz’s plan specified a $12m investment. Barron doubted that was enough so converted it into £12m (about $25m), doubled it again and then found that the NEB wanted to double it once more to £50m.

£50m in 1977 is around $500m in 2023 dollars. Today, that doesn’t seem that much at all to start a brand-new semiconductor manufacturer. As a day one investment in an unproven startup, though, it was an impressive sign of commitment.

But in an early sign of the difficulties of working with a state-sponsored body like the NEB, approval of the investment was controversial in the governing Labour Party. The NEB had previously invested in, or perhaps better to say ‘rescued’, failing businesses. Acting as a venture capital investor in a ‘high-tech’ startup was a radical departure. The NEB’s investment would eventually go all the way to the Cabinet of Prime Minister Jim Callaghan, who finally approved it, in the face of considerable opposition, in May 1978.

The new company needed a name. It started as EMOS, then KMOS before finally becoming Inmos.

Inmos would both design and manufacture chips, in both the UK and the US. The U.S. arm would start with a Fab and design centre in Colorado Springs. In the U.K., after a lot of political discussion and pressure, it embarked on the development of a Fab in Newport in South Wales. The building was designed by the leading (and presumably expensive) architect Richard Rogers. According to the architect’s website:

Logical, efficient, flexible and durable, and in its expressive use of services as sculpture, Inmos has something of the poetic quality of Pompidou and Lloyd’s.

The UK design centre would be located in Bristol in the west of England, which offered reasonable property prices and good links to Heathrow Airport for staff to travel across the Atlantic.

Memories

… there was a pattern of ambitious development and use of new technology that ran up against difficult commercial and practical realities.

The new company had little difficulty in recruiting engineers, either in the US or in Europe. There was one initial legal problem, though. Some of those engineers had been recruited from Mostek, leading to a lawsuit from Petritiz’s former company.

Many of the existing US memory makers were less than impressed with Inmos. At a time when they already faced intense competition from Japanese rivals, the idea of a new foreign backed memory startup ‘poaching’ engineers and, they thought, their designs, did not go down well. According to “The Inmos Saga”, the 1986 book on the story of Inmos:

“In so far as such a group of fierce competitors could be said to have a single opinion on anything, it did not take kindly to the idea of an outside interest, the British Government, deliberately buying parts of its available technology with the expressed aim of exporting it and then competing directly against the indigenous American industry.”

In the end, Inmos beat off the legal challenge from Mostek in a Dallas courtroom. They soon faced another personnel issue. The business plan specified that the first product would be a 64kb Dynamic RAM. But three key engineers with DRAM expertise were recruited by US memory rival, Micron Technologies.

So the focus turned to static RAMs and the first Inmos product was a 16Kb static RAM, the IMS 1400. Barron would later explain the focus on Static RAM (SRAM):

“Our first objective was to make static RAM, the high-performance memory which made the computers of the time and subsequent microprocessors really work. This was an interesting market because there was only one company, Intel, making static RAMs. Intel controlled the market, and made an enormous amount of money out of their 4K devices.

We thought we could get in there and do a good job. Another factor was that it was much easier to design a static RAM, and required less process development so that we could get to market more quickly. So our fundamental aim was to hit the 16K static RAM market first, before Intel or the Japanese. We thought the static RAM market was going to grow enormously with the computer business, as indeed it did.”

And the new company executed reasonably well on its memory strategy, leading with SRAMs but with 64Kb DRAMs to follow. There were some serious bumps along the way, though. The company ran into problems producing both DRAMs and SRAMs at Colorado Springs. Initial SRAM yields stayed stubbornly at around the 5% level, whilst the Fab at Newport in the UK was still a building site. According to Petritz:

“We overestimated our ability to make two different products at the same time in the same facility. The DRAM and SRAM required different processing steps and in a new building with inexperienced staff, at the beginning of the learning curve, it was especially hard to mix and match the two types of chip.”

Whilst these difficulties were being addressed, in 1981 the company soon encountered a severe downturn in the semiconductor market, but the decision to focus on SRAMs seem to be paying off. From the “The Inmos Saga”:

“… Intel had announced its own 16k static a year ahead of the IMS1400, and had been talking to the market about its own part but had never delivered. In 1981 Inmos fully expected Intel to become a competitor along with the Japanese, but neither immediately materialised and the company had a temporary monopoly.

Inmos had, however, been very aggressive in its use of technology; it was committed to the use of wafer-steppers and dry (plasma) etching for a lot of the process steps, both relatively new and untried techniques. Inmos was also the first company to use redundancy in a commercial chip. This latter feature helped increase yield in the long run but it took a while to get it working.

Such was the demand for its statics, however, that Inmos could sell them at over $100 each.”

The market for static RAMs wasn’t as big as INMOS had expected though, possibly because Intel’s absence had held the market back.

So there was a pattern of ambitious development and use of new technology that ran up against difficult commercial and practical realities. It was a pattern that would be repeated on the other side of the Atlantic too …

The Transputer

Just as modern computers were made up of many transistors that were linked together, so Barron thought that future computers would be made from many linked Transputers.

In Bristol, on the other side of the Atlantic, work had started on the development of the new Inmos microprocessor.

Barron thought that the future of computing was ‘parallel’ with many processors working at the same time. So he set out to design a processor specifically for this model.

The new design needed a name. Barron called it the ‘Transputer’ – combining ‘transistor’ and ‘computer’ – a name that he had had in mind for a while. Just as modern computers were made up of many transistors that were linked together, so Barron thought that future computers would be made from many linked Transputers. To be effective, these new processors would need to communicate with each other and so needed hardware to implement fast links between them.

Barron recruited a team of designers, led by David May and Robert Milne, to make his vision a reality. The problem was that May and Milne had incompatible views of the Transputer architecture.

Milne favoured a design specifically tailored to work with the Ada programming language. Ada was seem as the language of the future and other microprocessor designs, including, as we have seen, the ill-fated Intel iAPX432, were being built specifically to run Ada.

The opposing view thought that Ada was too complex. Influenced strongly by British computer scientist Tony Hoare, and with views that seem strikingly similar to those of computer scientists developing RISC architectures at Berkeley and elsewhere. Quoting ’The Inmos Saga”:

“What they all wanted was a new simplicity in computers, in their structure and in the languages used to program them. In this context, simplicity need not be the enemy of performance. Indeed, Barron and May thought a simply structured chip might be capable of far faster operation than the existing ranges of complex devices. By increasing the elegance of architectures and languages, the full potential of MOS chips – their ability to perform lots of elementary operations at speeds approaching that of light – could be fully harnessed.”

The dispute between the two camps rumbled on, until in the end Barron, who had been distracted with the politics associated with getting Inmos up and running, had to decide.

“In the end, Barron grew tired of waiting for a consensus to emerge from his team and decided to enforce his own preference. Along with May, Barron had decided that the transputer should be what others now describe as a ‘reduced instruction set computer’ (RISC). Instead of the hundreds of different types of instructions recognised by the most sophisticated conventional processor chips, the Transputer would only use a small number.”

So work on the design proceeded under David May’s direction. Not only would the Transputer use a radically new design, the Inmos team in Bristol would also develop brand-new tools to support its development. Deciding that existing tools weren’t powerful enough, they set up a team of five to build a new set of tools, codenamed Fat Freddy, after a hippie cartoon character, from scratch.

As we’ll see in this week’s supplemental post, the Transputer’s architecture would be very different to the ‘classic’ RISC designs such as RISC-I, MIPS and ARM that were emerging at the same time.

The first Transputer was announced in 1983 and the first silicon shipped in 1984, the year before the first ARM core.

The Transputer made it into the August 1984 edition of Byte magazine, where it was positioned as a competitor to the next generation of 16 and 32-bit microprocessors:

“The Transputer is Inmos's contender in the struggle over the next generation of microprocessors. It is pitted against the likes of the NS 16032 and the Intel 80286.”

The Transputer was very different from those designs, though. Each Transputer had a simple processor core, a small amount of memory and hardware to facilitate high speed serial communications with up to four other Transputers. The serial link meant that large numbers of Transputers could be connected to form a ‘compute farm’.

Most versions of the Transputer included ‘scheduler’ hardware that would pause any process that was waiting for data to be sent or received over the serial communication link. It could do this without needing the operating system to intervene to control the operation of the Transputer whilst this was happening.

This architecture meant that the Transputer had a lot in common with microcontrollers. Each Transputer could operate without much external circuitry. In fact, the Inmos team also envisaged the use of Transputers in many applications where microcontrollers then being used. The Transputer could even boot without access to an external Read Only Memory chip, with the Transputer receiving the code it needed to boot over its serial connection.

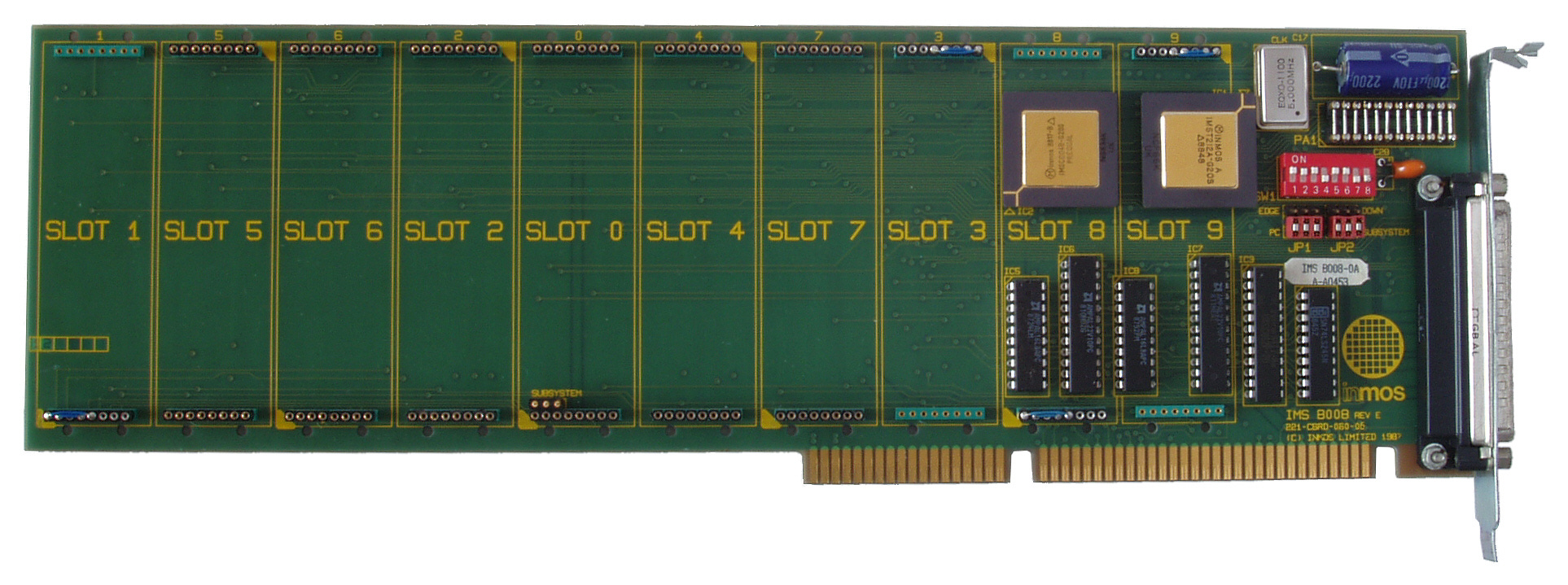

This enabled the construction of circuit boards with densely packed transputers to maximise processing power in a small space (for an example, see this Transputer board on David May’s home page.

There were three main series of Transputers that made it to production: T2, T4 and T8.

T2: The initial prototype Transputer was the T212, a 16-bit design that lacked scheduling hardware.

T4: The T414 appeared in October 1985 and was a 32-bit design with 4k of onboard memory.

T8: The T800 Transputer was introduced in 1987 added a 64-bit floating-point unit (FPU) and registers for floating point.

The Transputer could be programmed in traditional programming languages such as C, Pascal or Fortran. In each case, Inmos added libraries to their implementation of each language to support the parallel processing features of the Transputer.

The intention of the Inmos team though was that the Transputer would be programmed in a language that could properly exploit its features. Milne had favoured using Ada, before Barron again vetoed the idea. In the end, Barron, Hoare and May had a week-long brainstorming session in a hotel to develop the specification for the new language. Occam can claim some of the same heritage as Erlang. Both owe a lot to the idea of “Communicating Sequential Processes” as described by Hoare.

The language was named by Milne before he finally left Inmos. It would be called OCCAM after William of Occam, the author of Occam’s Razor. The original version of Occam’s Razor is sometimes translated as ‘Entities must not be multiplied beyond necessity’ which might not be the most appropriate association for a language designed to program parallel computing systems.

If you’d like to know more about the Transputer, then the paid supplement to this edition of The Chip Letter, out on Tuesday, has lots more detail on the Transputer, including a close look at its architecture and its instruction set.

Parallel Businesses

In the midst of the technical innovation of the Transputer and the commercial successes of the memory business, the company had some major problems. The reality of Inmos was that it was made up of two quite different companies on either side of the Atlantic. Petritz and his team in the US were mainly interested in the memory business. Barron would later say:

“There was enormous conflict between the US and UK. It was an underlying structural problem that went on for years. My US partners regarded the UK company as a tax on the investment capital they had received, and they wanted to lose the UK company as fast as they could. Clearly, my motivation was somewhat different.”

The reaction to the Transputer was, perhaps unsurprisingly, also mixed:

“The reactions of Inmos's American staff to the transputer saga had been somewhat bemused. Most Americans, both within the company and outside it, had been deeply impressed by the chip's intellectual concepts; Barron had addressed a huge audience at a Silicon Valley electronics exhibition in the autumn of 1983 and had been delighted with the warmth of the response. One American chip-maker had offered to make the transputer under licence, an offer Barron had refused until it could be negotiated on the more favourable terms made possible by having actual chips to sell. But the American Inmos employees could not understand the desperate need of those in Bristol to challenge every single convention of microcomputer design.”

To complicate matters even further, within six months of being funded by the Labour-led government in the UK, that government had been replaced by the new Conservative government led by Prime Minister Margaret Thatcher. Would Mrs Thatcher be supportive of a potential high-tech champion, or disdainful of a state-backed company that was not yet profitable?

We’ll find out in ‘Inmos and the Transputer – Part 2’, next time, when we’ll look at what happened to Inmos, the Transputer and the complex legacy that the company has left behind.

If you’ve like this post then you might like this, which discusses the development of RISC microprocessors taking place at about the same time as the Transputer.

The RISC Wars Part 1 : The Cambrian Explosion

I’d like to start this week’s post with a small confession. In last week’s post, I called Berkeley RISC-I ‘the first RISC microprocessor’. In fact, some believe that a derivative of the IBM 801, known as ROMP, was the first RISC microprocessor. The story of the 801’s successors, including ROMP, will be the subject of a later post. I believe that RISC-I …

Hi Babbage, yes the parallel architecture model and the overlay of Occam's processes onto the multi-proc h/w was ingenious and as I say, well ahead of its time. Also, not to be underestimated was the class leading nature of a 20Mbit serial link in the 80s! Use of this formed the basis of my degree project and found its way into avionics hardware in the 90s. The legacy lives on though - amongst others, one major success was the use of the 32bit T424 core in what became the ST20, which found it's way into a very large number of settop boxes in Europe. That core is now widely embedded elsewhere too. Happy days! What did you work on? That would be amusing if so!

Very fond memories of being one two Field Application Engineers with Inmos in the UK - helping customers design and develop their Transputer based systems. Fascinating times and, in hindsight Inmos and our parallel processing architecture was elegant, class leading, and well ahead of its time.